As one of the most high-risk industries, manufacturing requires strict adherence to Environmental, Health, and Safety (EHS) regulations. However, ensuring compliance with these regulations can be a daunting task, especially when relying on manual processes and systems. EHS software for manufacturing provides a comprehensive solution for managing safety, compliance, and environmental risks, with numerous features and benefits that help to streamline processes and improve productivity. In this article, we’ll examine the key components, features, and benefits of EHS software for manufacturing, and provide best practices for selecting and implementing the right solution.

Understanding EHS Software for Manufacturing

What is EHS Software?

EHS software is an integrated system that helps organizations manage environmental, health, and safety risks. It allows businesses to monitor compliance with EHS regulations, identify hazards, mitigate risks, and improve overall performance. EHS software for manufacturing is specifically designed to address the unique challenges facing the manufacturing industry.

Manufacturing facilities are often large and complex, with numerous moving parts and potential hazards. EHS software helps manufacturers stay on top of their safety and compliance obligations by providing a centralized platform for managing all aspects of EHS.

Importance of EHS in Manufacturing

EHS is not only critical for compliance and legal reasons; it also plays a vital role in ensuring the safety and well-being of all employees. Manufacturing involves a variety of hazardous materials, machinery, and processes, which can pose significant risks to workers if not properly managed.

By implementing EHS software, manufacturers can proactively identify and mitigate risks, reducing the likelihood of accidents, injuries, and illnesses. This not only protects employees, but also helps businesses avoid costly legal fees, fines, and reputational damage.

In addition, businesses that prioritize EHS are more likely to attract and retain talent, enhance their reputation, and increase customer loyalty, ultimately leading to increased profitability.

Key Components of EHS Software

The primary components of EHS software for manufacturing include:

- Incident management and reporting

- Risk assessment and mitigation

- Compliance management

- Training and awareness

- Environmental management

- Occupational health and safety

- Emergency preparedness and response

Each component is essential for the successful implementation and management of EHS software in manufacturing.

Incident management and reporting allows manufacturers to track and investigate safety incidents, near-misses, and hazards. This helps businesses identify patterns and trends, and take corrective action to prevent future incidents.

Risk assessment and mitigation involves identifying potential hazards and evaluating the likelihood and severity of associated risks. By implementing controls to mitigate these risks, manufacturers can reduce the likelihood of accidents and injuries.

Compliance management ensures that manufacturers are meeting all relevant EHS regulations and standards. This includes tracking permits, reporting requirements, and other compliance obligations.

Training and awareness is critical for ensuring that all employees are aware of potential hazards and know how to work safely. EHS software can help businesses track employee training and ensure that all workers are up-to-date on the latest safety protocols.

Environmental management involves monitoring and managing environmental impacts associated with manufacturing operations. This includes tracking emissions, waste, and other environmental factors.

Occupational health and safety focuses on ensuring that workers are healthy and safe while on the job. This includes tracking health and safety data, conducting regular inspections, and implementing controls to reduce risks.

Emergency preparedness and response involves developing and implementing plans for responding to emergencies, such as fires, chemical spills, and natural disasters. EHS software can help businesses develop and test these plans, ensuring that they are prepared for any eventuality.

Features of EHS Software for Manufacturing

Manufacturing is a complex industry that requires a lot of attention to detail and safety. EHS software for manufacturing is a valuable tool that can help businesses stay compliant with regulations, minimize risk, and promote a culture of safety. Here are some of the key features of EHS software for manufacturing:

Incident Management and Reporting

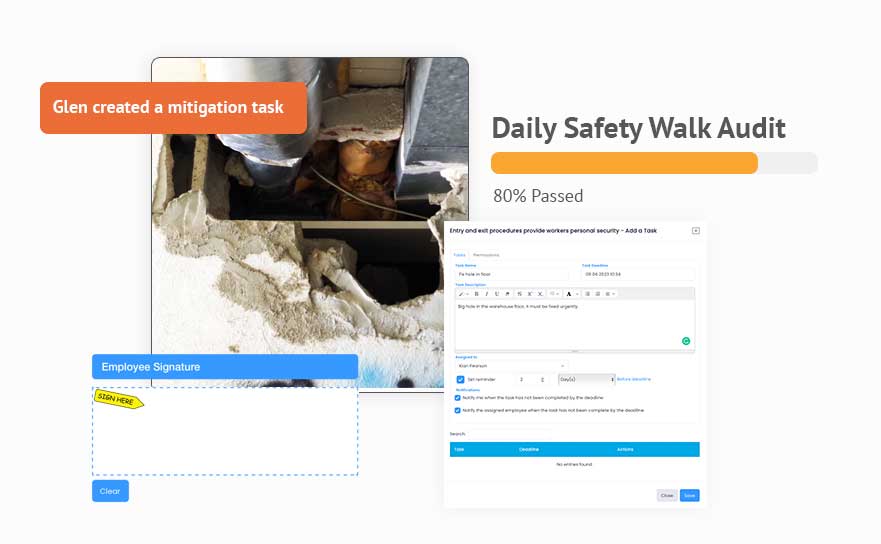

One of the most important features of EHS software for manufacturing is incident management and reporting. This tool allows for the easy reporting of incidents, near misses, and other safety events. It simplifies the process of tracking and investigating incidents and helps organizations identify trends and take corrective action to prevent future incidents.

For example, if an employee is injured on the job, the incident can be reported through the EHS software. The software will then automatically notify the appropriate people, such as the safety manager or HR representative. The incident can be tracked through the software, and any necessary corrective actions can be assigned and monitored until they are completed.

Incident Management With Evalu-8 EHS

Efficiently report incidents, so you can take corrective action and prevent future occurrences. With real-time tracking and detailed reporting, you can identify potential hazards and gain insights into your organization’s safety performance.

Risk Assessment and Mitigation

EHS software for manufacturing enables organisations to identify and assess potential hazards, including workplace accidents, environmental risks, and compliance violations. It provides tools for risk analysis and the development of risk mitigation plans to minimise exposure to risk.

For instance, if a manufacturing plant is located in an area prone to earthquakes, the EHS software can help identify the potential risks associated with earthquakes, such as equipment damage or employee injuries. The software can then be used to develop a risk mitigation plan, such as reinforcing equipment or conducting earthquake drills with employees.

Risk Assessment With Evalu-8 EHS

Designed to help you effortlessly create comprehensive risk assessments in just a few clicks. Say goodbye to time-consuming manual processes. With real-time insights, customisable templates, and seamless collaboration features, Evalu-8 EHS streamlines risk management.

Compliance Management

EHS software for manufacturing helps businesses stay compliant with a complex array of EHS regulations, including OSHA, EPA, and local regulations, among others. It simplifies compliance management by providing tools for tracking and managing permits, audits, and inspections.

For example, if a manufacturing plant is required to conduct monthly safety inspections, the EHS software can be used to schedule and track these inspections. The software can also be used to generate reports that demonstrate compliance with regulations, which can be useful during audits or inspections.

Training and Awareness

EHS software for manufacturing facilitates employee training and education, which is essential for promoting a culture of safety and compliance. It allows businesses to develop and deliver training programs, track participation, and assess the effectiveness of training initiatives.

For instance, if a manufacturing plant introduces a new piece of equipment, the EHS software can be used to develop and deliver training programs to employees who will be using the equipment. The software can track employee participation in the training and assess the effectiveness of the training program over time.

Training Management With Evalu-8 EHS

Evalu-8 EHS Health and Safety Training feature empowers your team to enhance workplace safety with comprehensive training solutions. Streamline your training process, reduce risk, and ensure compliance with ease.

Occupational Health and Safety

Software helps businesses ensure employee health and safety by providing tools for managing occupational health risks, tracking worker exposure to hazards, and managing medical programs and records.

For instance, if a manufacturing plant uses hazardous chemicals, the EHS software can be used to track employee exposure to these chemicals and monitor the effectiveness of protective equipment, such as respirators or gloves. The software can also be used to manage medical programs, such as employee health screenings or vaccinations.

Emergency Preparedness and Response

The right EHS software enables organisations to prepare for and respond to emergency situations, such as fires, spills, or natural disasters. It provides tools for developing emergency plans, conducting drills, and tracking response activities.

For example, if a manufacturing plant is located in an area prone to wildfires, the EHS software can be used to develop an emergency plan that outlines evacuation procedures and identifies safe areas for employees to gather. The software can also be used to conduct drills and track response activities during an actual emergency.

Overall, EHS software for manufacturing is a valuable tool that can help businesses improve safety, reduce risk, and stay compliant with regulations. By leveraging the features of EHS software, manufacturing companies can create a safer and more sustainable workplace for their employees.

Benefits of Implementing EHS Software

Implementing EHS (Environment, Health, and Safety) software in manufacturing can have a significant impact on the overall success of a business. Here are some of the key benefits:

Improved Safety and Compliance

One of the primary benefits of implementing EHS software is the improvement in safety and compliance. With EHS software, businesses can ensure compliance with EHS regulations, reduce the risk of accidents and injuries, and promote a culture of safety. This not only protects employees but also helps businesses avoid costly fines and legal issues.

For example, EHS software can help businesses track and manage safety incidents, conduct audits and inspections, and provide training and education to employees. This can lead to a safer and more compliant workplace.

Streamlined Processes and Reduced Costs

Another benefit of EHS software is the streamlining of processes and reduction in costs. EHS software can eliminate paper-based systems and reduce administrative burdens, resulting in increased efficiency and cost savings.

For instance, EHS software can automate tasks such as incident reporting, inspections, and compliance tracking. This reduces the need for manual data entry and paperwork, freeing up employees to focus on more important tasks. Additionally, EHS software can help identify areas where costs can be reduced, such as energy consumption or waste management.

Enhanced Employee Engagement

EHS software can also promote a culture of safety and compliance that engages employees at all levels of the organization. This can lead to improved morale, increased productivity, and a stronger sense of teamwork.

For example, EHS software can provide employees with access to safety training and resources, as well as opportunities to provide feedback and suggestions for improvement. This can help employees feel more invested in the success of the business and more connected to their colleagues.

Better Decision-Making with Data Analytics

EHS software provides powerful data analytics capabilities that help businesses identify trends, assess risk, and make informed decisions. This can lead to better decision-making and improved outcomes.

For instance, EHS software can help businesses identify areas where safety or compliance risks are highest, allowing them to prioritize resources and make targeted improvements. Additionally, EHS software can help businesses track and analyze data related to environmental performance, such as energy consumption or waste reduction, enabling them to make data-driven decisions about sustainability.

Increased Sustainability and Environmental Performance

EHS software can also help organizations monitor and manage their environmental impact, reduce waste and emissions, and promote sustainable practices. This not only benefits the environment but can also improve the reputation and bottom line of a business.

For example, EHS software can help businesses track and manage their energy consumption, water usage, and waste production. This can lead to reductions in resource usage and cost savings. Additionally, EHS software can help businesses identify opportunities for sustainable practices, such as using renewable energy sources or implementing recycling programs.

In conclusion, implementing EHS software in manufacturing can have a wide range of benefits, from improved safety and compliance to increased sustainability and cost savings. By leveraging the power of technology and data, businesses can create a safer, more efficient, and more successful workplace.

Best Practices for Selecting and Implementing EHS Software

Environmental, health, and safety (EHS) software solutions are essential for organisations looking to streamline their EHS management processes. These solutions help organizations manage compliance, reduce risk, and promote a culture of safety and sustainability. However, selecting and implementing the right EHS software can be a daunting task. Here are some best practices to help you select and implement the right EHS software for your organization.

Assess Your Organization’s Needs and Goals

Before selecting an EHS software solution, it is important to assess your organization’s current EHS policies and goals. This will help you identify the features and functionality that are critical to your business. You should also consider your organization’s size, industry, and regulatory requirements when assessing your needs.

For example, if your organization operates in a highly regulated industry, such as healthcare or pharmaceuticals, you may need an EHS solution that can help you manage compliance with regulations like HIPAA or FDA guidelines.

Involve Key Stakeholders in the Selection Process

It is important to involve key stakeholders in the selection process, including EHS professionals, IT staff, and end-users. This will ensure that the selected solution meets the needs of all parties involved. Involving end-users in the selection process can also help increase user adoption and reduce resistance to change.

For example, involving EHS professionals in the selection process can help ensure that the selected solution meets the organization’s EHS management needs, while involving IT staff can help ensure that the solution is compatible with existing IT infrastructure.

Evaluate and Compare EHS Software Solutions

When evaluating EHS software solutions, it is important to consider factors such as ease of use, scalability, integration, and cost. Comparing multiple solutions can help you select the one that best fits your organization’s needs.

For example, if your organization is growing rapidly, you may need an EHS solution that can scale with your organization. Similarly, if your organization already uses other software solutions, such as an enterprise resource planning (ERP) system, you may need an EHS solution that can integrate with your existing IT infrastructure.

Plan for a Smooth Implementation

A successful implementation requires careful planning, including data migration, system configuration, and user training. It is important to develop a plan that ensures a smooth transition to the new system.

For example, you may need to migrate data from existing EHS management systems to the new solution. You may also need to configure the new system to meet your organization’s specific needs.

Train Employees and Encourage the Adoption

Training is essential for user adoption and the success of your EHS software implementation. Develop a training plan that includes training materials, online tutorials, and onsite training sessions.

For example, you may need to provide training to end-users on how to use the new system, how to report incidents, and how to access EHS policies and procedures.

Continuously Monitor and Improve Your EHS Program

EHS software for manufacturing is not a one-time solution. Continuously monitoring and improving your EHS program will help you maintain compliance, reduce risk, and promote a culture of safety and sustainability. Regularly reviewing and updating your EHS policies and procedures can help ensure that your organization is meeting regulatory requirements and best practices.

For example, you may need to regularly review your EHS policies and procedures to ensure that they are up-to-date with the latest regulatory requirements. You may also need to conduct regular audits and inspections to identify areas for improvement.

By following these best practices, you can select and implement the right EHS software solution for your organization, and ensure that your EHS management processes are streamlined, efficient, and effective.

Top EHS Software Solutions for Manufacturing

Manufacturing is an industry that requires strict adherence to environmental, health, and safety (EHS) regulations. EHS software solutions have become essential for manufacturing companies to manage compliance and mitigate risk. In this article, we will explore some of the top EHS software solutions for manufacturing.

Overview of Leading EHS Software Providers

There are many EHS software providers in the market, but only a few have been able to establish themselves as leaders in the manufacturing industry. Some of the leading EHS software providers for manufacturing include:

- Evalu-8 EHS: Their platform offers a comprehensive suite of EHS applications, including compliance management, risk management, and sustainability management. You get all features for one price and there is no contract.

- Evotix: Another leading EHS software provider. Their platform is designed to help Enterprise level organisations manage EHS compliance, occupational health, and safety, and sustainability. It is modular, there is a minimum spend and a lengthy contract.

- HandsHQ: An option for companies that only require RAMS, it is a very limited platform but a one to consider if you are on a tight budget and only need RAMS.

Key Features and Benefits of Each Solution

Each solution has unique features and benefits that are tailored to the needs of specific organisations. It is important to evaluate each solution based on your organization’s needs and goals. Here are some key features and benefits of each solution:

- Evalu-8 EHS: Designed by industry experts, Evalu-8 EHS is the complete Health and Safety software solution for small to large manufacturing companies that want to centralise EHS management and have all the tools they need to ensure a safe and compliant working environment.

Unlike most systems it is not modular, we know you need a full suite of features to stay on top of EHS. There is no lengthy contract as we belive you should want to stay because the software is good enough, not because you are contractually obliged.

Evotix: Similar to Evalu-8 EHS, Evotix offers a full range of features to centralise EHS management. However, it is designed for enterprise-level companies, it is modular in terms of access to features and you need to sign year-long contracts.

Unless you have a large annual budget (£20,000+) and oversee a big operation we do not suggest Evotix.

HandsHQ: A very simple platform ideally suited to those just starting out on their EHS journey who want to digitise RAMS and training management. It is not a platform for full 360 H&S management but it is a starting point for small operations on a budget.

Tips for Choosing the Right EHS Software for Your Organization

When selecting EHS software for manufacturing, it is important to consider factors such as ease of use, scalability, integration, and cost. Evaluating multiple solutions and involving key stakeholders can help you select the right solution. Here are some tips for choosing the right EHS software for your organization:

- Assess your needs: Before selecting an EHS software solution, assess your organization’s needs and goals. Identify the key features and capabilities that are important for your organization.

- Consider ease of use: Choose a software solution that is easy to use and requires minimal training.

- Look for scalability: Choose a software solution that can grow with your organization and adapt to changing needs.

- Consider integration: Choose a software solution that can integrate with other systems and applications used by your organization.

- Compare costs: Compare the costs of different EHS software solutions and choose the one that offers the best value for your organization.

- Involve key stakeholders: Involve key stakeholders in the selection process to ensure that the software solution meets the needs of all departments and functions.

By following these tips and evaluating multiple EHS software solutions, you can select the right solution for your organization and ensure compliance with EHS regulations.

Conclusion: Achieving EHS Excellence in Manufacturing

The Role of EHS Software in Manufacturing Success

EHS software is an essential tool for businesses that prioritise safety, compliance, and sustainability. It allows organisations to identify, assess, and mitigate risks, streamline processes, and improve overall performance.

Embracing a Culture of Safety and Sustainability

Implementing EHS software for manufacturing is just the first step in achieving EHS excellence. It is also important to promote a culture of safety and sustainability by engaging employees and continuously improving your EHS program.

See Evalu-8 EHS in action

The leading choice of EHS software for small to large companies in the manufacturing sector that want to get control of there safety