Managing health and safety in a manufacturing environment isn’t easy. You’ve got incidents to report, RAMS to complete, audits to schedule, inspections to track, and training to stay on top of. And that’s before anyone even sets foot on the shop floor.

For many UK manufacturers, the challenge isn’t doing these things, it’s doing them efficiently. Paper systems, scattered spreadsheets, and clunky tools slow everything down.

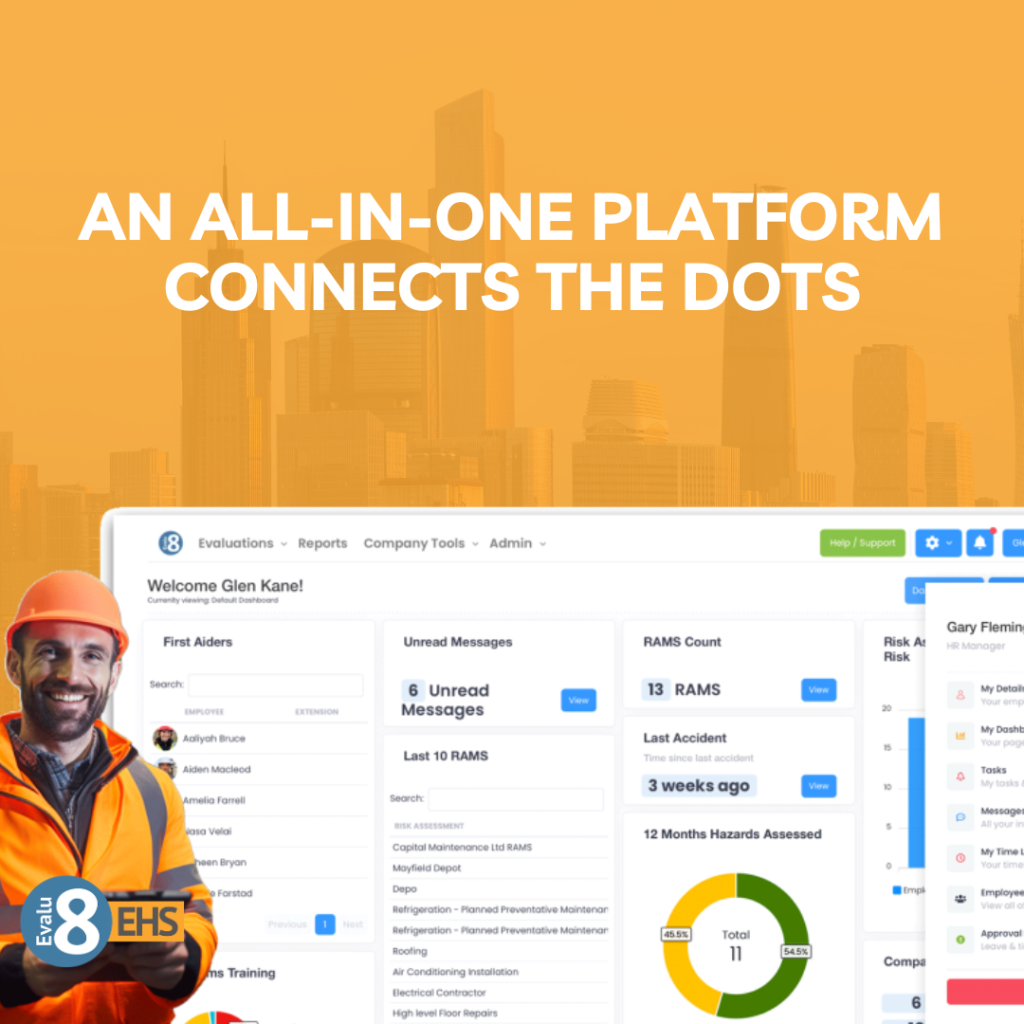

That’s why more manufacturers are switching to an all-in-one EHS platform, one that brings everything together, keeps everyone informed, and gives leaders the visibility they need to run safer, more compliant operations.

Helpful summary

Overview: This article explores how UK manufacturers are streamlining their EHS (Environmental, Health and Safety) processes by using a single software platform instead of juggling multiple systems.

Why trust us: Evalu-8 EHS works directly with manufacturers across the UK to simplify safety management. From RAMS to audits, training to fatigue monitoring, we’ve built a platform that’s made for manufacturing.

Why it matters: Poor EHS processes don’t just slow you down, they put your people and your business at risk. Using one platform helps you stay proactive, not reactive.

Action points: Look for a platform that combines incident reporting, audits, risk assessments, RAMS, inspections, training, and documentation, all in one place.

Further research: Take a look at Evalu-8 EHS in action by booking a guided walkthrough. No pressure, no jargon, just a quick look at how we help you save time, reduce risk, and stay compliant.

What’s going wrong with EHS right now?

Let’s face it, most manufacturers are dealing with a patchwork of systems. One platform for audits. A spreadsheet for inspections. Another tool for training records. And don’t forget the filing cabinet full of paper RAMS.

This siloed approach doesn’t just cause admin headaches. It leads to:

Duplicate work

Out-of-date documents

Lack of accountability

Missed review dates

Gaps in compliance reporting

And the bigger your operation gets, the worse the sprawl becomes.

What does an all-in-one EHS platform actually do?

An all-in-one platform connects the dots across your safety processes. It helps your team work faster, your records stay accurate, and your audits become less of a panic. Everything’s in one place, always up to date, and easy to access, no more guesswork or chasing people for updates.

The key features manufacturers need

If you’re choosing an EHS platform, these features aren’t nice-to-haves, they’re essentials:

Incident and near-miss reporting: Real-time, mobile-friendly, and fully trackable.

RAMS builder: Create, share, and update RAMS from reusable templates.

Audit and inspection tools: Schedule, assign, and log outcomes with full visibility.

Training management: Store certificates, track renewals, and assign learning.

Document control: Keep policies and procedures versioned and accessible.

Reporting and dashboards: See what’s going well—and where the risks are building up.

Why Evalu-8 EHS is the smart choice for UK manufacturers

When it comes to simplifying EHS, Evalu-8 EHS brings everything together in one powerful, flexible platform. Built with input from manufacturers, it’s designed to work on the ground, not just in the boardroom.

Everything you need, all in one place

With Evalu-8 EHS, you don’t need five different tools. You get incident reporting, risk assessments, RAMS, audits, training records, inspections, COSHH tracking, and even fatigue management, all under one roof.

Designed for real-life teams

The platform is easy to use, whether you’re on a desktop in the office or using a tablet on the shop floor. No steep learning curves or technical jargon, just a system your team will actually want to use.

Keeps you compliant, without the scramble

From automated reminders to RIDDOR-ready reports, Evalu-8 EHS helps you stay ahead of HSE requirements. When audit time comes around, you’re ready, no last-minute digging for documents.

Scales with your business

Whether you’re managing one site or ten, Evalu-8 EHS lets you assign permissions, set up site-specific reporting, and get a centralised view of all your EHS activity.

Real benefits from using one platform

The shift to a single platform isn’t just about convenience, it brings real, measurable benefits.

Manufacturers using one platform report:

Faster incident reporting and close-outs

Fewer missed review dates and compliance gaps

Improved team accountability and ownership

Easier audits and better data visibility

More time spent on proactive safety work—not admin

When your systems work together, so do your people.

EHS doesn’t have to be complicated

If your current setup feels like a juggling act, you’re not alone. But EHS management doesn’t have to be this hard, or this disjointed.

With a platform like Evalu-8 EHS, you can bring clarity, control, and consistency to every part of your safety process. It’s simple. It’s scalable. And it’s built for the way manufacturers actually work.

Still deciding? These common questions might help

Yes. Evalu-8 EHS is designed to replace separate tools for incidents, audits, RAMS, training, and more with one integrated platform.

Most manufacturers are up and running in a few weeks. Our team helps with onboarding, data import, and training, so nothing gets missed.

Absolutely. You can manage multiple locations with site-specific access, reporting, and visibility from one central dashboard.

Evalu-8 EHS includes customisable dashboards and exportable reports, so you can track performance, spot trends, and share results with stakeholders.

Yes, your team can use any device to complete checks, log incidents, or view documents, even offline when needed.