Helpful summary

Choosing the right EHS software is critical for UK maritime businesses navigating complex safety risks, regulatory obligations, and dynamic project environments. From confined space entries and COSHH compliance to working at height and PPE checks health and safety in marine operations demands precision, documentation, and accountability.

But with so many platforms out there, which software is truly fit for purpose when it comes to shipyards, engineering vessels, and dry dock operations?

In this guide, we compare the top EHS software solutions for maritime businesses in 2025. Whether you’re overseeing hull repairs, managing crew safety, or tracking confined space entries, this list will help you find a platform that works as hard as your team does.

Overview:

This guide, brought to you by Evalu-8 EHS, compares the best EHS software options for maritime businesses in 2025. It reviews each platform’s suitability for dockyards, vessel maintenance, and offshore operations highlighting strengths in confined space safety, RAMS, COSHH tracking, inspections, and more.

Why trust us:

Evalu-8 EHS is trusted by UK organisations in high-risk sectors like construction, engineering, logistics, and maritime. We’ve designed our platform to manage everything from welding permits to fire watch schedules because reactive H&S systems don’t belong on active docks.

Why it matters:

Shipyards and marine engineering firms face some of the UK’s most demanding health and safety environments. The right EHS platform will reduce incidents, improve audit outcomes, and give supervisors full visibility over risk-critical tasks without drowning your team in paperwork.

Action points:

Use this guide to compare features, pricing models, and use-case suitability. Whether you’re running a dry dock or a design-and-build yard, the right software will help you move from “compliance chaos” to real-time control.

Evalu-8 EHS – Best all-in-one EHS software for maritime operations

Why Evalu-8 EHS stands out for maritime

Evalu-8 EHS is a modular, UK-built health and safety platform designed for complex environments like shipyards, dry docks, and marine engineering projects. Built with real-world compliance in mind, it handles the safety challenges of confined space work, hazardous substances, working at height, and rotating shifts.

For dock supervisors, project managers, and safety leads, Evalu-8 centralises risk documentation, PPE checks, RAMS briefings, and incident logs all accessible via mobile. Tasks can be tied to vessel phases, project milestones, or individual teams.

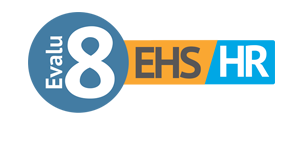

Maritime-relevant features

Permit-to-Work Management

Digital issuance and tracking of confined-space, hot-work, electrical isolation, and crane-lift permits. E-signatures, expiry reminders, and lockout/tagout checklists keep all permits current and auditable.

Document Management & Version Control

Central library for safety manuals (e.g., SDS, equipment SOPs, welding procedures), drawings, and engineering documents—accessible on-site and shore-side—with full version history and access logs.

COSHH compliance: Manage paints, solvents, anti-fouling chemicals, and fuels.

Corrective Action & CAPA Tracking

Create, assign, and monitor corrective or preventive tasks directly from audit findings or incident reports. Due-date reminders and status dashboards ensure timely closure.

Equipment & Machinery Inspection

Scheduled inspections of cranes, forklifts, hoists, dry-dock blocks, gantry systems, and other heavy equipment. Capture condition ratings, attach photos/videos, and flag defects for immediate action.

Customisable Safety Checklists

Pre-built and fully configurable audit and inspection templates for key shipyard activities—welding, blasting, painting, machining, lifting, and hot works—ensuring compliance with ISO 45001, SOLAS, and local regulations.

Task automation: Set fire watch rotas, assign inspection follow-ups, and track overdue actions.

Incident & Near-Miss Logging

Streamlined reporting forms tailored to shipyard scenarios (e.g., dropped objects, chemical exposures, pinch-point injuries), with photo attachments or site-zone tagging, and immediate notifications to supervisors.

Advanced features

Fatigue management: Highlight risks from shift rotations and long hours.

Role-Based Dashboards & Permissions

Grant shop-floor supervisors, safety managers, and corporate EHS teams bespoke views: supervisors see work-area KPIs; managers see overdue actions and trend reports; executives see high-level compliance metrics.Multi-site setup: Manage multiple dry docks or yards in a single interface.

Pricing

Starts at £2.50 per user/month. Modular add-ons for RAMS, COSHH, training, audits, fatigue, Risk Assessments and more. Pricing is transparent, scalable, and tailored to your setup.

Explore Evalu-8 EHS

Pros & cons

Pros:

-

Built for UK compliance: Covers RAMS, COSHH, confined space permits, and audits with a UK regulatory focus.

-

Modular and scalable: Only pay for the features you need, perfect for SMEs or growing dock operations.

-

Confined space and RAMS workflow: Tie permits, sign-offs, and inspections to specific vessel work.

-

Fatigue risk tools: Unique in this list for managing shift patterns and real-time fatigue alerts.

-

Mobile-friendly: Teams can log incidents, complete checklists, and access documents on-site or offshore.

Cons:

-

No built-in eLearning library: You’ll need to upload your own SCORM or link to third-party training content.

-

Custom dashboards may need light setup: While powerful, some reporting views benefit from initial configuration support.

EcoOnline

EcoOnline is a solid option for organisations dealing heavily with hazardous substances, but it lacks the operational fluidity and maritime-specific workflows that shipyards and dockside teams often need. While it shines in COSHH and chemical compliance, it can feel clunky for day-to-day RAMS workflows, confined space permitting, or mobile-first inspections. Setup requires commitment, and pricing isn’t transparent making it harder for smaller teams to evaluate without going through sales.

Core features

-

COSHH Management: Create and store chemical safety data sheets (SDS), log hazardous substances, and generate COSHH assessments.

-

Incident Reporting: Log workplace incidents and near-misses, assign investigations, and follow up corrective actions.

-

Audit & Inspection Tools: Schedule audits and inspections with follow-ups, status tracking, and version history.

-

Training Management: Assign and track compliance training, renewal cycles, and certification status.

-

Permit to Work: Create and manage high-risk permits such as hot works or confined space access.

-

Document Control: Store policies, procedures, and certificates in one secure location.

Advanced features

-

Emergency Preparedness: Build response protocols and manage emergency drills and plans.

-

Contractor Management: Track contractor compliance, onboarding, and documentation status.

-

Asset & Equipment Tracking: Maintain inspection schedules, servicing logs, and asset histories.

-

Real-Time Dashboards: Visualise overdue tasks, compliance rates, and key metrics across multiple sites.

-

Lone Worker Support: Tools and integrations to protect workers in isolated conditions.

Constraints and functionality gaps

-

Pricing Transparency: No public pricing available. Must request a tailored quote, which can slow early research and budgeting.

-

Setup Complexity: High level of configurability comes with a steep implementation curve. Many users report the need for dedicated internal resources or external consultants during onboarding.

-

Learning Curve: Admin users often require in-depth training to access full functionality. Even basic configurations can be unintuitive without prior experience.

-

Limited Mobile Functionality: While the app is useful for inspections and reporting, it lacks the full power of the desktop version. Some advanced workflows (e.g. document editing, dashboard customisation) are only available on desktop.

-

Confined Space Workflow Limitations: No dedicated tools to tie permits, RAMS, and sign-offs to specific confined space entries this must be manually managed via general permit tools.

-

Reporting Flexibility: While reporting is solid, it can lack real-time customisation for project-based or vessel-specific views, which marine teams often rely on.

-

No Fatigue Management Tools: For shipyards with long shifts or rotating patterns, there is no built-in functionality to assess or track fatigue risk.

-

Maritime Context Gaps: Lacks pre-built templates or workflows tailored to maritime or dockyard-specific hazards (e.g. hull entry, drowning risk, firewatch scheduling).

Pricing

EcoOnline uses a modular, quote-based pricing model. No public pricing is listed on their website, which means potential customers must go through a sales process to get ballpark figures. While this enables flexibility and customisation, it also adds friction to the evaluation phase, especially for SMEs comparing multiple vendors.

Pros & cons

Pros:

-

Excellent COSHH and chemical safety tools

-

Strong permit-to-work and document management features

-

Real-time dashboards help monitor compliance

-

Suitable for large or multi-site organisations

-

UK-based customer success teams available

Cons:

-

No transparent pricing must request a quote

-

Setup and onboarding can be time-consuming and resource-intensive

-

Limited mobile capabilities compared to competitors like Evalu-8 or SafetyCulture

-

Lacks dedicated confined space and fatigue risk tools

-

No maritime-specific workflow support

-

Requires training to use advanced configuration or reporting features effectively

Work Wallet

Work Wallet is a lightweight, mobile-friendly EHS tool built around real-world usage logging incidents, tracking audits, and delivering toolbox talks on the go. But while it’s simple and effective for daily frontline tasks, it lacks depth in critical areas like RAMS, COSHH, fatigue, and multi-site management. For complex maritime operations, its flexibility hits a ceiling, making it better suited to subcontractors or small dock teams rather than large-scale yards or marine projects.

Core features

-

Incident Reporting: Log incidents with rich media (photos, GPS, categories), and track follow-up actions.

-

Audits & Inspections: Conduct mobile checklists with template-based reporting and version control.

-

Risk Assessments: Build and manage general risk assessments with template guidance.

-

Toolbox Talks: Deliver, log, and track toolbox talks digitally, ensuring team briefings are consistent and recorded.

-

Digital Inductions: Prepare new workers or contractors with digital onboarding, including document uploads and sign-offs.

-

Permit to Work: Issue and track digital permits for high-risk activities.

-

Job Management: Schedule and assign jobs/tasks with completion status and basic compliance checks.

Advanced features

-

Safety Cards: Digital employee safety profiles with training, qualifications, and competency records.

-

Contractor Gateway: Portal for external parties to manage and upload safety documentation before site access.

-

ID & Training Records: Keep training matrices and employee certs centralised and easily accessible.

-

Multi-device Access: Compatible with desktop, tablet, and mobile for access across roles and work environments.

Constraints and functionality gaps

-

No Dedicated RAMS Builder: There’s no purpose-built RAMS module. Users must manually create documents or store externally.

-

Limited COSHH Functionality: Lacks dedicated chemical or substance safety tools, which is critical in maritime operations involving paints, fuels, or solvents.

-

No Fatigue Risk Tools: No tools to manage or track shift patterns, working hours, or fatigue risks common in shipyards.

-

Basic Risk Assessments: Risk modules are suitable for general hazards but don’t support dynamic, multi-phase assessments tied to specific vessels or project milestones.

-

Reporting Limitations: While basic summaries exist, reporting lacks depth for trend analysis, incident categorisation by phase, or safety milestone tracking.

-

No Asset or Equipment Management: No modules to manage gas detectors, PPE expiry, or fire system checks.

-

Desktop Dependency for Admin Tasks: While field use is mobile-friendly, setup, customisation, and some reporting must be done via desktop.

-

Integration Gaps: Other than Azure Active Directory, there’s limited integration with external systems like HR, ERP, or scheduling tools.

-

Not Designed for Multi-site Oversight: No site grouping, filtering, or high-level compliance dashboards across multiple yards.

Pricing

Work Wallet starts at approximately £1 per user per month, depending on modules selected. The platform uses a modular pricing structure, meaning businesses only pay for features they need. Custom quotes are required for larger implementations or multi-site rollouts. This pricing is competitive but reflects the platform’s limited depth in more advanced areas.

Pros & cons

Pros:

Very user-friendly mobile app for frontline safety actions

Great for toolbox talks, inductions, and incident logging

Digital safety cards and contractor portal support small teams

Low cost with modular flexibility

Cons:

-

No purpose-built RAMS or COSHH modules

-

Lacks tools for fatigue, asset, or equipment management

-

Reporting and dashboard tools are limited

-

Doesn’t scale well for multi-site maritime businesses

-

Admin and advanced features limited to desktop

-

Not suitable for complex regulatory environments

RAMS App

RAMS App is a no-frills, document-first safety tool aimed at UK contractors who need quick access to risk assessments and method statements. While it’s fast, simple, and template-rich, the system lacks the depth and automation required for larger shipyards or marine firms. Without a dedicated mobile app, real-time task tracking, or asset/PPE oversight, it feels more like a document vault than a fully-fledged EHS platform.

Core features

-

Risk Assessment Templates: Access hundreds of pre-written, trade-specific templates.

-

Method Statement Builder: Edit and issue trade-focused method statements (RAMS) via desktop.

-

COSHH Assessment Access: Use thousands of pre-loaded COSHH examples or build custom ones.

-

Training Record Management: Store training certificates and manage toolbox talk delivery logs.

-

Document Archiving: Save and archive older documents, helping maintain compliance trails.

-

Digital Signatures: Enable signing off on RAMS, method statements, and safety docs digitally.

Advanced features

-

Custom Trade Libraries: Tailor templates based on trade (e.g. welders, scaffolders, painters).

-

Document Duplication: Speed up issuing RAMS by cloning similar project templates.

-

Cloud Document Access: Retrieve all safety docs via browser access no install needed.

-

Team Access Controls: Manage user permissions and assign documents per team or site.

Constraints and functionality gaps

-

No Dedicated Mobile App: Users access documents via mobile browser. There’s no offline mode, push notifications, or native mobile audit functionality.

-

No Real-Time Task Tracking: Can’t assign actions, track inspections, or follow up on overdue tasks.

-

No Audit or Inspection Module: Audits must be built manually and stored like other documents; no photo uploads or checklist tracking.

-

No Equipment Management: No system to log inspections or track fire extinguishers, gas detectors, or harness checks.

-

Lack of Project Linking: RAMS can’t be tied to specific vessel build phases or project timelines.

-

No Alerts or Reminders: Lacks automation for training expiry alerts, overdue assessments, or safety task reminders.

-

No Fatigue Risk Support: Doesn’t assess or report on shift patterns, long working hours, or fatigue exposure.

-

Minimal Reporting: No real-time dashboards, safety KPIs, or incident frequency reports.

-

Limited Integration: No integration with third-party HR, scheduling, or maintenance platforms.

-

No Change Management or Permits: No structured workflow for managing permit-to-work or change risk.

Pricing

Pricing starts at £399 per year for a single user (ex VAT), which includes RAMS, COSHH, and training modules. Multi-user accounts are priced based on team size, and custom quotes are required for larger groups. A free trial is available. Cost-effective for small contractors but expensive per-user if scaled without added capability.

Pros & cons

Pros:

-

Vast library of ready-made RAMS and COSHH content

-

Digital signatures and role-based access

-

Simple to use, ideal for small teams or sole traders

-

Cloud-based with no software install needed

Cons:

-

No mobile app or offline access

-

No real-time task tracking or follow-up tools

-

No audit, equipment, or fatigue features

-

Poor scalability for multi-phase marine projects

-

Lacks automation, reporting, and integration

SafetyCulture

SafetyCulture is a sleek, mobile-first tool with powerful checklist and inspection capabilities but it’s not a comprehensive EHS platform. While it works well for field inspections, hazard reporting, and tracking corrective actions, it falls short for complex health and safety needs in shipyards or engineering docks. Maritime teams will quickly find themselves layering in spreadsheets or additional tools for RAMS, COSHH, and fatigue. A good bolt-on, but rarely the full answer.

Core features

-

Custom Audit Checklists: Build inspection templates for scaffolding, tool checks, confined space prep, and more.

-

Issue Reporting: Log hazards, near misses, or unsafe conditions in real time via mobile or tablet.

-

Corrective Actions: Assign and track fixes, with reminders and evidence capture.

-

Training Management: Track safety training status and create microlearning content.

-

Analytics: Visualise audit results and trends with built-in reports and charts.

Advanced features

-

Template Library: Access pre-made templates for H&S inspections and modify to suit.

-

Integrations: Connect with Microsoft Teams, Power BI, Tableau, and Zapier to push/pull safety data.

-

Asset Management: Log inspections on equipment/tools, though not a full asset lifecycle system.

-

API Access: Build custom workflows or dashboards by integrating with internal systems.

-

Permissions & Role Management: Control who can see, assign, or action specific items.

Constraints and functionality gaps

-

No RAMS Capability: There is no way to build or manage formal risk and method statements within the platform.

-

No COSHH Management: Doesn’t support SDS tracking, hazardous substance logging, or exposure controls.

-

Limited Fatigue Tools: No visibility over working patterns, shift risk, or fatigue exposure.

-

Not Built for Maritime: No templates or modules tailored to marine-specific hazards (e.g. hull entry, oxygen deficiency, sea-based operations).

-

Offline Functionality Is Patchy: While mobile access is a strength, offline use can be unreliable in some regions, and syncing delays occur.

-

Data Silos Risk: If using SafetyCulture alongside other platforms (e.g. HR or permit systems), there’s a risk of duplicate data entry without full integration.

-

Pricing at Scale: Once you move beyond small teams, pricing can escalate quickly compared to more modular systems like Evalu-8.

-

Not an End-to-End Platform: Best used for inspections only won’t replace a proper EHS management system with training matrices, audits, incident case files, or safety project tracking.

Pricing

SafetyCulture offers three plans:

-

Free Plan: Up to 10 users with 5 templates and limited data storage.

-

Premium: $24 per user/month (approx. £19), includes unlimited templates, analytics, permissions, and integrations.

-

Enterprise: Custom pricing with enhanced support, SSO, and security layers.

While the free plan is generous for testing, most maritime teams will outgrow it quickly. The Premium plan is solid but adds up fast if scaled across multiple teams, projects, or yards.

Pros & cons

Pros:

-

Excellent for mobile audits, inspections, and hazard capture

-

Modern, intuitive interface that teams pick up quickly

-

Robust checklist builder with templates and issue tracking

-

Integrates well with third-party BI and communication tools

Cons:

-

No RAMS, COSHH, or fatigue management functionality

-

Not purpose-built for marine or high-risk environments

-

Offline mode can be unreliable in field conditions

-

Costs can escalate at scale

-

Requires layering with other tools for full H&S compliance

EHS Insight

EHS Insight offers a broad, flexible EHS platform with strong capabilities in audits, risk assessments, and training. It’s configurable and scalable, but its generalist nature and US-focused base mean it often misses the mark for UK maritime-specific needs like confined space workflows, fatigue tracking, and COSHH documentation. It can work well with enough customisation but out of the box, it may require workarounds and setup time to make it fit dockyard or shipyard realities.

Core features

-

Incident Management: Log, investigate, and follow up on safety incidents or near misses.

-

Audit & Inspection Management: Schedule and perform safety audits using templates with automatic corrective action logging.

-

Risk Assessments: Create and manage general workplace risk assessments.

-

Training Tracking: Monitor training records, track renewals, and manage certifications.

-

Document Control: Store, version, and retrieve safety documents and procedures.

-

Compliance Monitoring: Track HSE requirements and regulatory performance.

Advanced features

-

AI-Enhanced Insights: Some analytics and dashboard modules are powered by machine learning to identify risk trends or gaps.

-

Behaviour-Based Safety: Log safety observations and drive improvements based on proactive employee behaviours.

-

Management of Change: Structured process to evaluate risks linked to changes in processes, people, or equipment.

-

Industrial Hygiene Tools: Monitor environmental hazards like noise, air quality, and heat exposure.

-

Customisable Dashboards: Create role-specific views for supervisors, project leads, or safety managers.

Constraints and functionality gaps

-

No Built-In RAMS Support: There’s no purpose-built module for RAMS. Any method statements or risk controls must be handled manually or adapted via general forms.

-

No COSHH-Specific Tools: Lacks a chemical register, SDS database, or COSHH assessment workflows.

-

UK Compliance Alignment: The system is not natively built around UK regulations like COSHH, CDM, or HSE guidance. It can be configured, but not without effort.

-

Maritime Blind Spots: No out-of-the-box tools for confined space management, hull access permitting, or vessel-specific safety workflows.

-

Fatigue Risk Unsupported: No shift pattern analysis, rest tracking, or alerts tied to excessive hours or safety-critical fatigue triggers.

-

Mobile App Limitations: While mobile-enabled, some complex tasks (like configuration or advanced reporting) are restricted to desktop.

-

Reporting Setup Required: Dashboards and reports are powerful but often need IT or vendor support to align with industry-specific views.

-

Customisation Trade-Off: While flexible, the depth of configuration can overwhelm teams without dedicated internal safety/tech resource.

Pricing

EHS Insight uses a subscription pricing model starting from around £3,500/year for SMEs. Costs scale based on the number of users, modules selected, and required support. While competitive compared to enterprise platforms, costs rise quickly when scaling into multiple teams or adding complex reporting.

Pros & cons

Pros:

-

Flexible and modular platform covering most core EHS areas

-

Strong tools for audits, training, and general risk management

-

AI-powered insights and modern dashboard functionality

-

Mobile app with offline access

-

Good fit for safety-led teams wanting control over configuration

Cons:

-

No native RAMS or COSHH functionality

-

Not built for UK regulatory or maritime use cases

-

Requires time and expertise to customise effectively

-

No fatigue or confined space workflow management

-

Reporting setup can be technical or resource-heavy

Cority

Cority is a feature-rich, enterprise-grade EHS platform used globally across regulated industries like pharmaceuticals, oil & gas, and manufacturing. While it delivers exceptional breadth, it’s often more software than maritime SMEs or UK-based shipyards need. Implementation is heavy, configuration is complex, and pricing is rarely transparent. For smaller marine teams, Cority may feel bloated, with critical workflows buried in complex modules that require dedicated system admins.

Core features

-

Incident Management: Full lifecycle tracking of incidents from report to closure, with corrective actions and root cause analysis.

-

Occupational Health: Medical surveillance, case management, and health assessments.

-

Environmental Management: Track emissions, spills, and waste handling across projects.

-

Risk Assessments: Advanced risk matrix tools with configurable control measures.

-

Training & Competency: Assign, track, and audit training records across teams and departments.

-

Document Control: Manage, version, and distribute controlled documents.

Advanced features

-

Ergonomics & Industrial Hygiene: Assess exposure to hazards like noise, heat, or repetitive motion.

-

Configurable Workflow Engine: Tailor approval flows, notifications, and dependencies.

-

Data Visualisation: Create board-ready dashboards and visual analytics across EHS metrics.

-

Audit & Compliance Management: Schedule and document internal/external audits, inspections, and regulatory checks.

-

Mobile Access: Capture incidents and perform audits offline with native mobile apps.

-

Sustainability & ESG Reporting: Report on ESG initiatives and align with corporate goals.

Constraints and functionality gaps

-

Complex Configuration: Powerful but complex. Most customers require specialist consultants or in-house system admins to maintain workflows and reporting.

-

Not UK/Maritime Focused: While versatile, Cority is built with global enterprise in mind. It does not offer pre-configured RAMS tools, COSHH compliance modules, or marine-specific workflows (e.g. hull access, vessel-phase tracking).

-

No Dedicated RAMS Builder: RAMS are not a core module and would need customisation to implement effectively.

-

Limited COSHH Integration: SDS and substance management exists but is more aligned to manufacturing/HSE than to shipyard or solvent-heavy trades.

-

No Fatigue Risk Management: Lacks specific tools to assess working hour exposure, shift rotation risk, or fatigue warnings.

-

High Cost of Ownership: From licensing to onboarding and support, Cority can be prohibitively expensive for smaller businesses.

-

Slow Implementation: Projects can take several months to configure and deploy, especially with complex workflows or third-party integrations.

-

Steep Learning Curve: Users need structured onboarding and training. Some modules are unintuitive out of the box.

-

Overkill for SMEs: Many features go unused in smaller organisations or maritime companies focused on RAMS, audits, and incident tracking.

Pricing

Cority follows a fully customised pricing model with no publicly listed tiers. Costs depend on:

-

Number of users

-

Modules selected

-

Implementation complexity

-

Level of ongoing support or integration required

Typical implementations run into tens of thousands per year, with additional costs for onboarding and configuration.

Pros & cons

Pros:

-

One of the most comprehensive EHS suites available globally

-

Strong analytics, health surveillance, and environmental tracking

-

Excellent scalability for large, multi-site organisations

-

Mobile apps with offline access

-

Deep configuration potential for complex businesses

Cons:

-

Overengineered for small to mid-sized maritime businesses

-

No built-in RAMS, COSHH, or fatigue workflows

-

Expensive and time-consuming to implement

-

Lacks maritime or confined space safety templates

-

Requires technical expertise to maintain effectively

Sphera

Sphera is a comprehensive EHS and sustainability suite tailored to highly regulated, enterprise environments. While it excels in compliance monitoring, ESG reporting, and environmental risk management, it’s not well-suited to hands-on safety work in shipyards or engineering vessels. With no built-in RAMS or COSHH workflows, a steep onboarding curve, and opaque pricing, Sphera is more boardroom tool than dockyard solution.

Core Features

-

Health & Safety Management: Log incidents, perform root cause analysis, and assign corrective actions.

-

Environmental Reporting: Monitor emissions, waste, water usage, and compliance with environmental permits.

-

Operational Risk Management: Track operational hazards and regulatory controls across departments.

-

Corporate Sustainability: Align EHS with ESG goals and report on sustainability metrics.

-

Document Management: Secure storage with version control for procedures, policies, and compliance records.

Advanced Features

-

Analytics & Dashboards: In-depth visualisation of safety, compliance, and ESG performance.

-

Regulatory Content Libraries: Stay aligned with global compliance frameworks through integrated content updates.

-

Mobile Access: Field teams can log issues and complete safety forms via mobile app.

-

Risk Frameworks: Configurable enterprise risk frameworks for operational control across business units.

-

Audit & Compliance Scheduling: Automate inspections and internal audits across global operations.

Constraints and Functionality Gaps

-

No RAMS Module: No native support for risk and method statements. Teams must create these manually or outside the platform.

-

No COSHH or SDS Management: The platform doesn’t include built-in tools for chemical safety management, which is critical in marine environments.

-

Not Designed for Maritime Workflows: No confined space tools, vessel-phase project tracking, or scaffolding/hull inspection features.

-

No Fatigue Risk Monitoring: No capability to assess fatigue based on working hours, shift history, or real-time workload.

-

Limited Frontline Usability: Field teams may find the platform cumbersome for everyday incident reporting or task management compared to simpler tools like Evalu-8 or Work Wallet.

-

Pricing Complexity: No public pricing; tailored quotes make it difficult for SMEs or dock operators to evaluate feasibility early.

-

Resource-Heavy Setup: Implementation is complex and requires both technical and process owners to map, test, and deploy each module.

-

Enterprise-Focused UX: The interface, while powerful, is not optimised for rapid on-the-ground use.

-

Overbuilt for Mid-Sized Teams: Many of its strengths are underutilised by teams with fewer than 500 users or those not focused on ESG frameworks.

Pricing

Sphera uses a quote-based pricing model with pricing dependent on:

-

Number of users

-

Selected modules (EHS, ESG, Operational Risk, etc.)

-

Scope of configuration and support

Costs are typically in the enterprise bracket often requiring board approval and multi-year commitments.

Pros & Cons

Pros:

-

Extremely strong for enterprise-wide compliance and sustainability reporting

-

Advanced analytics and configurable risk frameworks

-

Supports global regulatory standards

-

Well-suited for companies with dedicated EHS, ESG, and compliance teams

-

Scalable across large, multi-location organisations

Cons:

-

No COSHH or RAMS capabilities for marine use

-

Not user-friendly for frontline or project-based work

-

Implementation is complex and time-consuming

-

No fatigue or confined space workflow support

-

Overkill for most UK maritime organisations or contractors

Evotix

Evotix positions itself as a modern, people-first safety platform, designed to engage employees and promote proactive safety behaviour. It’s visually sleek and strong in mobile incident reporting and training micro-content. However, it lacks depth in core areas vital to maritime businesses such as RAMS, COSHH, and confined space workflows. Better suited to businesses focused on safety culture campaigns than to shipyards managing real-world risks under tight regulation.

Core Features

-

Incident Reporting: Simple, mobile-friendly tools for logging incidents, near-misses, and unsafe conditions.

-

Risk Assessments: Create and manage general safety risk assessments with approval workflows.

-

Audits & Inspections: Build audit templates and conduct inspections across worksites.

-

Training & Microlearning: Deliver bite-sized, app-based training and track completions.

-

Document Management: Store and distribute key documents like toolbox talks, procedures, and certificates.

-

Compliance Monitoring: Assign actions, track completion, and monitor adherence to regulatory tasks.

Advanced Features

-

ESG & Sustainability Reporting: Built-in tools for tracking environmental and social performance.

-

Occupational Health Tracking: Support for medical surveillance and worker health monitoring.

-

Custom Dashboards: Visualise safety KPIs, overdue actions, or site-level compliance in real time.

-

Behaviour-Based Safety: Capture observations and promote a proactive safety mindset among workers.

-

Mobile Offline Access: Allows safety reporting in areas with no connectivity, syncing later.

Constraints and Functionality Gaps

-

No Dedicated RAMS Module: Cannot create or assign formal Risk and Method Statements, which are a legal and practical necessity in marine work.

-

Limited COSHH Functionality: No built-in chemical inventory, SDS tracking, or solvent/fuel safety management essential for shipyards.

-

No Confined Space Permit System: Lacks structured permit workflows or entry tracking for tanks, bilges, or enclosed compartments.

-

No Fatigue Risk Analysis: No ability to assess working hour exposure, shift risks, or cumulative fatigue critical in docks and night-shift operations.

-

Not Maritime-Specific: No templates or built-in workflows for vessel inspections, hull access, firewatch rotas, or lift plan tracking.

-

Customisation Complexity: While configurable, deeper customisations require support from the Evotix team or internal IT.

-

Learning Curve for Admins: New users report the need for structured onboarding, especially for reporting and dashboard configuration.

-

Reporting Gaps: Standard reporting is solid but lacks real-time safety milestone tracking or integration with vessel/project phases.

-

Mid-Tier Scalability: Works well for businesses under 500 users; larger rollouts may require integration work to scale effectively.

Pricing

Evotix offers a fully bespoke pricing model:

-

Quotes depend on number of users, selected modules, and required support.

-

No public pricing available.

-

Typically positioned for mid-sized to large organisations, with pricing reflecting that tier.

Pros & Cons

Pros:

-

Modern UI with excellent mobile reporting and offline mode

-

Strong safety culture and engagement tools

-

Useful for safety observations, training, and behaviour-based initiatives

-

ESG tracking adds long-term sustainability value

-

Good UK support and compliance background

Cons:

-

No RAMS, COSHH, or confined space management

-

Lacks fatigue risk and shift tracking tools

-

Requires customisation for maritime workflows

-

Reporting not built for vessel-based operations

-

Pricing is not transparent or entry-level

Ideagen EHS

Ideagen EHS (formerly Q-Pulse WorkRite) is designed to unify safety, quality, and compliance management making it ideal for organisations with overlapping ISO or audit requirements. While it brings strong tools for training, incident management, and audits, its interface feels dated, and it lacks built-in maritime-specific workflows like RAMS, COSHH, or vessel-level inspections. Best suited to businesses already using Ideagen products or looking for QHSE alignment—not for shipyards needing agile, task-based EHS control.

Core Features

-

Incident Management: Record, investigate, and close incidents with full audit trail.

-

Audit & Inspection Tools: Schedule audits with checklist templates, assign actions, and monitor completion.

-

Risk Assessments: Perform basic risk assessments with controls and approval paths.

-

Training Tracking: Monitor training completion, expiry, and certifications across teams.

-

Document Management: Store, update, and control key safety and quality documentation.

-

Compliance Monitoring: Track regulatory obligations and completion of assigned safety actions.

Advanced Features

-

Behaviour-Based Safety: Capture and monitor safety observations and positive behaviours.

-

Change Management: Assess risks and compliance impact when changing tools, materials, or methods.

-

Industrial Hygiene: Monitor air quality, noise levels, or chemical exposure if configured.

-

Mobile App with Offline Access: Conduct audits or report incidents even in areas with no signal.

-

Sustainability Reporting: Align safety with broader ESG and sustainability metrics.

Constraints and Functionality Gaps

-

No RAMS Builder: Doesn’t support the creation or sign-off of Risk and Method Statements.

-

No COSHH/SDS Management: No dedicated COSHH toolset or hazardous substance tracking.

-

Lacks Confined Space Workflow: No system to manage permits, entry logs, or tank inspections.

-

No Fatigue or Shift Tools: Can’t monitor or alert for excessive working hours or pattern-based fatigue.

-

Marine Use Not Supported Natively: No templates or tools for scaffolding, hull access, fire watches, or lift plan audits.

-

Admin Learning Curve: Setup and dashboard configuration can be time-intensive.

-

Interface Dated in Areas: UI is functional but less modern and intuitive than newer platforms.

-

Requires Project Support: Onboarding and customisation are not simple self-service processes.

-

Mid-Level Customisation Only: While flexible, workflows may not offer the depth needed for vessel/project-specific compliance.

Pricing

Ideagen EHS follows a tailored pricing model based on:

Users

Modules selected

Required integration/suppor

No prices are listed online. Designed for businesses already operating in ISO-compliant environments or those expanding across EHS and quality.

Pros & Cons

Pros:

-

Good overlap between quality and safety for ISO-certified teams

-

Strong audit, training, and document control tools

-

Mobile app with offline access

-

UK-based vendor with local support

-

Well-suited to internal audits and cross-functional compliance

Cons:

-

No RAMS, COSHH, or confined space management

-

No fatigue or shift pattern tools

-

Interface can feel dated and unintuitive

-

Requires training and support for advanced setup

-

Not tailored to maritime workflows or project-based safety tracking

Choosing the Right Maritime EHS Platform

When it comes to managing health and safety in shipyards, dry docks, and marine engineering projects, not all EHS software is built equal. Many platforms offer generic tools for audits, incidents, and training but few understand the real complexity of confined space permits, COSHH documentation, fatigue risk, or firewatch scheduling tied to specific vessels and project phases.

If your maritime operation needs a system that:

Supports formal RAMS workflows with sign-off

Manages COSHH for paints, solvents, and fuels

Tracks fatigue exposure across rotating shifts

Enables inspections, audits, and toolbox talks by site or vessel

Offers task automation and mobile access with real-time control…

Then Evalu-8 EHS stands out as the most comprehensive and cost-effective solution for UK maritime teams in 2025.

Where most competitors fall short either in complexity, price, or maritime relevance Evalu-8 delivers targeted tools for the risks you actually face, without the bloat you don’t need.

We encourage you to contact any vendor listed and conduct additional research to determine the best fit for your organisation.

FAQs

Yes. Risk and Method Statements (RAMS) are a legal and operational necessity in shipbuilding and repair. A dedicated RAMS module ensures your documents are properly created, briefed, signed off, and linked to project phases or vessel work reducing human error and improving audit readiness.

Evalu-8 EHS allows you to tie RAMS, permits, and sign-offs directly to confined space entries. Supervisors can ensure proper documentation and inspections are completed before work begins, and all logs are digitally tracked for safety and compliance.

Yes. Platforms like Evalu-8 EHS, Work Wallet, and SafetyCulture offer mobile functionality, with some including offline access. This ensures inspections, incident logging, and audits can still happen on vessels or in remote dry docks even when internet connectivity is limited.

Prices vary widely. Lightweight tools like RAMS App start from £399/year, while full-featured platforms like Evalu-8 EHS begin at just £1.25/user/month. Enterprise systems like Cority or Sphera require custom quotes and often cost thousands annually. The right choice depends on your team size, risk profile, and regulatory demands.