Renewable energy projects whether wind farms, solar arrays, biomass plants or anaerobic digestion sites present complex health and safety challenges. Technicians work at height on turbines, navigate confined spaces inside towers, manage high-voltage electrical systems, and handle flammable gases and battery materials. Tracking site access RAMS, COSHH data for lubricants and gases, and scheduling inspections across remote locations is critical to prevent incidents and ensure compliance.

Helpful summary

Overview: This article, brought to you by Evalu-8 EHS, provides a detailed comparison of the top six EHS software platforms tailored for the UK renewables sector in 2026. We evaluate core functionalities, advanced modules, known limitations, pricing models and suitability for wind, solar, biomass and anaerobic digestion operations.

Why Trust Us: At Evalu-8 EHS we specialise in UK-focused modular safety software. Our experience working with renewable energy companies informs our analysis of key features such as work-at-height RAMS, confined space permits, COSHH tracking for gases and battery materials, geo-tagged asset inspections and cross-site incident analytics.

Why It Matters: Renewables safety failures can lead to falls from height, arc flash injuries, gas exposures and costly downtime. Robust EHS software centralises RAMS, COSHH, inspections and incident reporting, helping site leads and operations managers maintain consistent compliance, reduce risk and demonstrate due diligence during audits and insurance reviews.

Action Points:

Identify your key requirements: turbine access RAMS, COSHH for gas handling, confined space permits, geo-tagged inspections, cross-site dashboards.

Trial shortlisted systems to confirm mobile and offline performance at remote wind and solar sites.

Assess pricing models based on headcount, site count and required modules.

Choose the platform that scales with your project portfolio and integrates with existing ERP or asset management systems.

Evalu-8 EHS: Best all-in-one renewables platform

Why Evalu-8 EHS stands out

Evalu-8 EHS offers a comprehensive, modular safety solution built for UK renewables. Site leads can assign task- and location-specific RAMS for turbine and panel access, enforce confined space and high-voltage sign-offs, manage COSHH for lubricants and battery materials, schedule geo-tagged inspections, and log incidents in real time. Its offline-capable mobile app, transparent pricing and UK-based support make it ideal for multi-site wind, solar and biomass operations.

Core Features

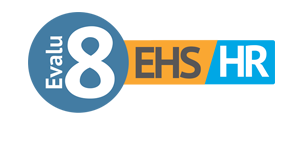

RAMS builder: Pre-configured templates for wind turbine access, roof-mounted solar installations, confined space entry and high-voltage panel work. Digital sign-off with version tracking.

COSHH register: Central SDS library for lubricants, biomass gases and lithium battery materials, with automatic renewal alerts.

Mobile inspections: Custom checklists for turbine condition surveys, solar array performance audits, biomass boiler inspections and gas monitor calibrations. Photo and GPS tagging.

Incident reporting: Log falls, arc flash events, gas exposures and near misses with attachments, assign investigation workflows and track corrective actions.

Task management: Recurring maintenance schedules, overdue inspection alerts and automated corrective-action assignments.

Document control: Store safety briefings, COSHH logs and RAMS packs with electronic signatures and permission settings.

Advanced features

Real-time dashboards: Geo-tagged incident heatmaps, site risk profiles and compliance scorecards across all remote locations.

Fatigue-risk assessment: Analyse shift patterns to flag tired crews working on turbines and panel installations.

Multi-site oversight: Group data by wind farm, solar park or biomass site for streamlined management and compliance reporting.

Automation and alerts: Schedule recurring inspections, COSHH renewals and training expiry reminders via email or SMS.

Explore Evalu-8 EHS

Pricing

Modules start at £100 per month.

Pros & cons

Pros:

Complete renewables-specific workflow covering RAMS, COSHH, inspections, incidents and training.

Mobile-first with robust offline capability for remote sites.

Transparent modular pricing and UK-based support.

Cons:

No native e-learning library.

Specialty templates require initial setup.

High-level analytics may need professional services to configure.

RAMS App

RAMS App excels at generating detailed risk assessments and method statements quickly. It offers a library of renewable-specific templates for wind turbine entry, roof-level solar work, confined space in biomass units and high-voltage safety protocols. While documentation is fast and mobile-responsive, there is no native incident-logging or COSHH register, and no task-tracking features, so additional systems are needed for full compliance management.

Core features

Risk assessment builder: Pre-written templates for work-at-height on turbines, solar panel installations, confined biomass pits and electrical hazard mitigation.

Method statement templates: Editable documents covering safe procedures, control measures and emergency plans for renewable tasks.

COSHH assessment templates: Thousands of pre-written forms for gas handling, battery chemicals and fire-suppressant materials.

Digital signatures: Secure e-sign workflows for site leads and technicians.

Version control: Archive previous assessments and method statements with time stamps.

Cloud storage: Access documents from any device with an internet connection.

Advanced features

Bulk duplication: Clone RAMS for similar tasks across multiple sites (e.g. repeating turbine access procedures on each wind farm).

Document archiving: Maintain historical records for audit and insurance purposes.

PDF export: Download signed RAMS packs for distribution to teams or subcontractors.

Email alerts: Notify stakeholders when new RAMS are created or updated.

Constraints and functionality gaps

No mobile app; relies on mobile browser, which can be slower in poor network areas.

No incident reporting module; cannot log falls, gas exposures or electrical shocks.

No integrated asset or equipment inspection functionality (e.g. harness checks, gas monitor service).

No training management or COSHH register features beyond simple form fields.

No task or corrective-action workflows; manual follow-up required.

Pricing

Single-user plans start at £399 per year. Team pricing by quote, with volume discounts for multiple users.

Pros & cons

Pros:

Extremely fast RAMS and method-statement generation.

Robust library of renewables-focused templates.

Affordable for basic documentation needs.

Cons:

Not a full EHS solution; lacks incident, inspection and task modules.

No offline or dedicated mobile app.

Requires additional platforms for end-to-end compliance.

SafeSmart

SafeSmart offers a mobile-first inspection platform designed to streamline asset checks and compliance reporting in renewables. Wind farm and solar park technicians can use custom checklists for turbine blade condition, panel alignment, gas monitor calibration and safety system tests. While strong in inspection management and compliance dashboards, it lacks a full RAMS builder and comprehensive COSHH register, requiring other tools for complete renewables safety management.

Core features

Custom inspections: Build checklists for wind turbine condition, solar array performance, biomass boiler safety and gas monitoring.

Media capture: Attach photos, videos and voice notes for immediate evidence of faults or hazards.

Offline capability: Conduct inspections in remote areas and sync once connectivity is restored.

Compliance dashboards: View inspection completion rates, overdue tasks and site performance metrics in real time.

QR-code deployment: Link specific checklists to turbine bases, solar field sections or biomass units via QR codes.

Automated reminders: Schedule recurring inspections and notify technicians before due dates.

Advanced features

Analytics and reporting: Generate trend reports on inspection pass rates, incident hotspots and asset health scores.

Integration options: Connect data to Power BI, maintenance management systems or SCADA platforms for broader oversight.

Role-based access: Restrict who can view or edit inspection templates by user role or facility.

API connectivity: Sync inspection results with ERP or CMMS systems for work-order creation.

Constraints and functionality gaps

No native RAMS or method-statement authoring capabilities.

COSHH management limited to file uploads; no interactive register or automatic reminders for hazardous chemicals.

No incident or near-miss reporting module integrated with tasks.

No training matrix or fatigue-risk assessment features.

Advanced reporting and integration require premium pricing tiers.

Pricing

Subscription starts at £10 per user per month for basic inspection modules. Enterprise plans with advanced analytics and API access on request.

Pros & cons

Pros:

Excellent mobile and offline inspection functionality for remote renewables sites.

Comprehensive compliance dashboards and analytics.

Flexible integration with external systems.

Cons:

Lacks RAMS authoring and full COSHH workflows.

No incident or training modules.

Advanced features locked behind higher pricing.

Evotix

Evotix provides a strong platform for engaging technicians in proactive safety through behavior-based observations, microlearning modules and recognition badges. Teams at wind, solar and biomass sites receive short, targeted training content and can log near misses or unsafe acts. While it supports incident management and mobile checklists, it lacks a full RAMS builder, robust COSHH register and detailed task management, making it a complement rather than a complete renewables EHS system.

Core features

Incident and near-miss reporting: Mobile capture with photo, GPS and immediate assignment of corrective tasks.

Behavior-based observations: Log safe or at-risk behaviors during turbine or panel maintenance, encourage positive safety habits.

Microlearning modules: Short training content on work-at-height protocols, arc flash avoidance, gas handling and confined space entry.

Mobile checklists: General safety walkthroughs for wind farm maintenance, solar panel row inspections and biomass facility housekeeping.

Engagement dashboards: Track observation counts, recognition badges and training completion rates by site or region.

Document repository: Store safety alerts, RAMS packs and emergency procedures for quick mobile access.

Advanced features

ESG and sustainability tracking: Monitor carbon footprint metrics for renewable operations and share progress with stakeholders.

Occupational health monitoring: Record exposures to biomass gases, repetitive strain from panel work and perform trend analysis.

Custom dashboards: Build site-specific KPIs such as near-miss frequency, training participation and observation rates.

Collaboration integrations: Connect with Microsoft Teams or Slack to broadcast safety alerts or share best-practice tips.

Constraints and functionality gaps

No built-in RAMS or method-statement workflows for project-specific tasks.

COSHH management limited to basic file uploads; no automated chemical expiry or SDS reminders.

No fatigue or lone-worker monitoring, which is critical for remote turbine or panel work.

Mobile checklists lack renewables-specific templates out of the box.

Pricing is quote-based and not transparent for smaller operations.

Pricing

Custom quotes based on user count and selected modules. No published rates.

Pros & cons

Pros:

Excellent for fostering proactive safety culture and engagement.

Microlearning modules target renewables-specific hazards.

Integrated ESG tracking and occupational health features.

Cons:

Not a standalone solution for full renewables EHS workflows.

Lacks RAMS and COSHH automation.

No fatigue or lone-worker tools.

Cority

Cority (formerly Medgate) is a robust EHS suite suited for large-scale renewable energy operators. It covers incident management, audit scheduling, environmental compliance, asset lifecycle tracking and extensive reporting. However, its complexity and cost make it less suitable for smaller wind or solar projects. Implementation can be lengthy and requires dedicated IT resources.

Core features

Incident and case management: Log falls from height, arc flash incidents, gas exposure events and near misses; assign investigations and track CAPA processes.

Audit and inspection scheduling: Plan turbine blade inspections, solar panel performance checks, biomass gas leakage tests and confined space audits with versioned reports.

Environmental compliance: Monitor emissions from biomass combustion, track waste streams and report against sustainability targets.

Asset management: Record inspection history for harnesses, gas monitors, fire suppression systems and electrical gear on each turbine or panel array.

Training and competency tracking: Manage mandatory refresher training on work-at-height, electrical safety and hazardous chemical handling for thousands of technicians.

Document control: Central repository for RAMS packs, COSHH SDS, safety procedures and corporate policies with strict version control.

Advanced features

Data visualisation: Interactive dashboards showing incident trends, audit compliance, asset reliability, and training gaps across entire renewable portfolios.

Mobile field solutions: Capture incidents and conduct inspections via tablet or smartphone, even when offline.

Custom workflow engine: Automate approval chains for high-risk tasks, CAPA follow-ups and multi-site sign-offs.

Regulatory reporting: Generate audit-ready reports for HSE regulators and insurance providers, including detailed root-cause analyses.

Constraints and functionality gaps

High total cost of ownership – licensing, implementation and ongoing support can be expensive for mid-sized operators.

Implementation timeline is long; often requires 3–6 months of consultancy and IT involvement.

No embedded renewables-specific RAMS templates out of the box; requires custom build.

Mobile app configuration may need professional services to optimize for remote site work.

Complexity can overwhelm smaller teams without dedicated EHS or IT staff.

Pricing

Custom enterprise pricing with multi-year contracts. Significant setup and consulting fees.

Pros & cons

Pros:

Comprehensive EHS and compliance capabilities at scale.

Powerful reporting, visualization and audit functionality.

Scalable to hundreds of remote sites and thousands of users.

Cons:

Prohibitively expensive for small-mid sized renewables projects.

Long implementation and steep learning curve.

Lacks pre-built renewables-specific templates.

EcoOnline

EcoOnline excels in managing hazardous substances and permit-to-work processes critical for biomass gas handling, battery storage sites and transformer oil maintenance. It provides a cloud-based COSHH register, SDS access, permit workflows and contractor management. While strong in chemical safety, it lacks detailed RAMS building for wind or solar work and has limited mobile inspection features, making it less comprehensive for full renewables operations.

Core features

COSHH & chemical register: Centralised SDS library for biomass gases, lubricants, battery electrolytes and fire suppressants, with automated expiry and reordering alerts.

Permit-to-work: Create and manage hot-work, confined space and high-voltage permits with approval workflows and risk ratings.

Incident logging: Record chemical spills, gas leaks and exposure events, assign corrective actions and track closure status.

Contractor management: Track subcontractor qualifications, insurance documents and compliance records for on-site work.

Audit scheduling: Plan and record gas system checks, fire suppression system tests and battery storage inspections with versioned checklists.

Training management: Assign and track COSHH, forklift, electrical safety and gas-handling courses, with notifications for renewals.

Advanced features

Real-time dashboards: Monitor chemical safety metrics, permit status, incident heatmaps and contractor performance across all sites.

Emergency response planning: Build and store emergency procedures for gas leaks, fire events and battery failures, with drill schedules.

Mobile app: Perform permit requests, capture inspection data and log incidents via smartphone, even offline.

Integration options: Connect with ERP, CMMS and HR systems for streamlined data flow and work-order creation.

Constraints & functionality gaps

No dedicated RAMS or method-statement builder for turbine or panel access tasks.

Inspection module is basic—lacks custom checklist builder for renewables-specific audits.

No fatigue monitoring or lone-worker check-ins for remote maintenance crews.

Advanced analytics and mobile features require premium pricing tiers.

Onboarding and customisation can be time-consuming due to deep configurability.

Pricing

Quote-based pricing; modular structure means you pay for selected features. No public rates listed.

Pros & Cons

Pros

Best-in-class COSHH and permit-to-work management for chemical risks.

Mobile permit requests and incident logging with offline support.

Strong contractor compliance and training management modules.

Cons

Does not handle detailed RAMS creation for wind or solar tasks.

Inspection functionality is not as robust as specialised audit tools.

Expensive customisation and premium features add to total cost.

Final Thoughts

Renewables industry safety demands a solution that handles work-at-height RAMS, confined space and high-voltage sign-offs, COSHH for gases and battery materials, geo-tagged inspections and cross-site incident analytics. While each platform excels in certain areas RAMS App is unmatched for quick risk statements, SafeSmart leads in mobile inspections, Evotix drives safety culture, Cority scales to enterprise operations, EcoOnline dominates chemical safety Evalu-8 EHS stands out as the most comprehensive renewables-specific system. Its modular design, robust mobile/offline capabilities, transparent pricing and UK-based support make it the ideal choice for wind, solar, biomass and anaerobic digestion projects in 2026.

FAQs

Evalu-8 EHS offers tailored RAMS templates for wind turbine access and geo-tagged inspection checklists ideal for remote sites, with offline mobile capability for technicians.

EcoOnline provides a comprehensive COSHH register with SDS management and expiry alerts specifically for biomass gases, lubricants and battery electrolytes, ensuring full compliance.

Both Evalu-8 EHS and SafeSmart support offline mobile inspections. Technicians can complete checklists for panel performance and safety rounds, then sync data when back online.

Yes. Evalu-8 EHS, Evotix and Cority centralise incident logging with GPS tags, allowing operations managers to view cross-site incident trends, heatmaps and compliance scorecards.

RAMS App excels at quickly generating risk assessments and method statements for work-at-height, confined space and high-voltage tasks, using pre-written templates tailored to renewables industry needs.